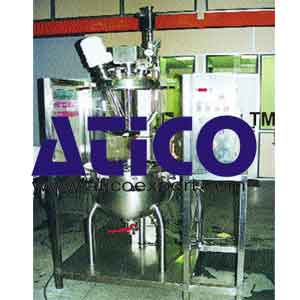

Vacuum Evaporator

Categories: Technical Educational EquipmentVacuum Evaporator This apparatus allows concentration under vacuum conditions of food and biological products : Vacuum Evaporator Apple juice concentration. Concentrated sugared milk manufacturin...

Product

Description

Vacuum Evaporator

This apparatus allows concentration under vacuum conditions of food and biological products :

Vacuum Evaporator- Apple juice concentration.

- Concentrated sugared milk manufacturing.

- Tomato sauce concentration.

- Fermented musts concentration.

Teaching objectives

- To establish material balance on the evaporator.

- To establish energy balance on the condenser.

- To study the pressure influence and the agitation speed on evaporation time.

- To study the pressure influence on the boiling point temperature of the product.

- To calculate the conduction heat transfer coefficients in agitated tank.To calculate Reynolds number of the agitator.

- To calculate Reynolds number of the agitator.

Technical specifications

A platform-mounted laboratory model with wheels made of :- A tank equipped with a soldered and sealed double jacket containing the product.

- Material: stainless steel 304L.

- Surface state: grain 320 (inner) grain 220 (outer).

- A variable-speed scraping agitator with setting potentiometer.

- An anchor with variable speed motor power 0,75 kW.

- Tank displacement by manual jack.

- Tank rotation around an axis for washing after treatment of difficult products.

- Safety sensor indicating tank presence before starting the agitator.

The tank includes :

- 1 Pt100 temperature probe.

- 1 exhaust ball valve.

- 1 funnel for product introduction.

- 1 glass observation window on the top of the tank.

- 4 fittings, safety valve, control manometer.

- 1 vacuum control valve, connection of the vacuum unit.

- 1 plunging cane mounted on SMS plug for sampling

The double wall circuit is made of :

- 2 threaded fittings (20/27).

- 1 Pt100 probe for the double jacket input temperature.

The safety control panel includes :

- Observation window with lighting.

- Cover opening and lifting control.

- Agitator control, speed control with display.

- Vacuum pump control and protection.

- Heating unit safety device

Dimensions

- 1000 x 1000 x 1900 mm.

Essential requirements

- This apparatus needs the vacuum generator unit and the heating unit.

- Total consumption with and : 7 kW.

- Power supply: 380 V (3P + Gr + N).

quick overview :

Vacuum Evaporator

This apparatus allows concentration under vacuum conditions of food and biological products :

Vacuum Evaporator- Apple juice concentration.

- Concentrated sugared milk manufacturing.

- Tomato sauce concentration.

- Fermented musts concentration.

Teaching objectives

- To establish material balance on the evaporator.

- To establish energy balance on the condenser.

- To study the pressure influence and the agitation speed on evaporation time.

- To study the pressure influence on the boiling point temperature of the product.

- To calculate the conduction heat transfer coefficients in agitated tank.To calculate Reynolds number of the agitator.

- To calculate Reynolds number of the agitator.

Technical specifications

A platform-mounted laboratory model with wheels made of :- A tank equipped with a soldered and sealed double jacket containing the product.

- Material: stainless steel 304L.

- Surface state: grain 320 (inner) grain 220 (outer).

- A variable-speed scraping agitator with setting potentiometer.

- An anchor with variable speed motor power 0,75 kW.

- Tank displacement by manual jack.

- Tank rotation around an axis for washing after treatment of difficult products.

- Safety sensor indicating tank presence before starting the agitator.

The tank includes :

- 1 Pt100 temperature probe.

- 1 exhaust ball valve.

- 1 funnel for product introduction.

- 1 glass observation window on the top of the tank.

- 4 fittings, safety valve, control manometer.

- 1 vacuum control valve, connection of the vacuum unit.

- 1 plunging cane mounted on SMS plug for sampling

The double wall circuit is made of :

- 2 threaded fittings (20/27).

- 1 Pt100 probe for the double jacket input temperature.

The safety control panel includes :

- Observation window with lighting.

- Cover opening and lifting control.

- Agitator control, speed control with display.

- Vacuum pump control and protection.

- Heating unit safety device

Dimensions

- 1000 x 1000 x 1900 mm.

Essential requirements

- This apparatus needs the vacuum generator unit and the heating unit.

- Total consumption with and : 7 kW.

- Power supply: 380 V (3P + Gr + N).

Product

Reviews

add Review

reviews

No Review Yet.

Product

Reviews

add Review

reviews

No Review Yet.